ALL NEW WellTech 5!

The WellTech 5 Rig Floor Tubing Inspection System

The WellTech 5™ Rig Floor Tubing Inspection System is the fifth generation of our popular WellTech product line. The new WellTech 5 is better equipped than ever to deliver fast, accurate inspections right on the rig floor. Utilizing advanced non-contact transverse and wall sensor technology, the WellTech 5™ ensures excellent assessments of tubing condition as it’s pulled from the well. The exclusive SPLIT-CHECK pneumatic split and hole detector offers unmatched flaw detectability. The SPLIT-CHECK can detect holes and splits closer to the coupling than other EMI/Eddy current systems, as it is not affected by the magnetic end effect. The WellTech 5 is also our most compact model to date.

Decreased Maintenance and More Longevity

Say goodbye to time-consuming maintenance routines. The WellTech 5™ features an innovative design with an updated non-contact transverse and wall monitoring sensor system paired with a low-maintenance pneumatic split and hole detector. These enhancements not only minimize upkeep but also extend the lifespan of internal components so you can focus on what truly matters—efficient and reliable inspections.

Advanced Detection for Service-Induced Flaws

The WellTech 5™ is equipped with a state-of-the-art solid-state Hall effect detection system, expertly designed to identify common service-induced flaws in used tubing, including pitting, cracks, rod wear, and wall thinning. This sophisticated system encircles the tubing within a powerful DC magnetizing coil, delivering comprehensive inspections as the tubing is extracted from the well.

Product Specifications

| Technical and Performance Data | |

| Capacity: | 2 3/8" to 4 1/2" O.D. (with coupling) |

| Functions: | Transverse flaw detection (MFL) TRUEWALL™ magnetic wall thickness monitoring (MFD) SPLIT-Check split and hole detector |

| Data Acquisition: | Data acquisition system with Dell laptop computer (all functions performed on computer with multi-color data display) |

| Production Rate: | Up to 150 ft. / min |

| Major Components: | Electronics console Dell laptop computer with WellTech software and Well Profile Report Power and signal cables Powerful magnetizing coil Inspection canister Detector insert kits with split detector and tubing standards (sizes optional) |

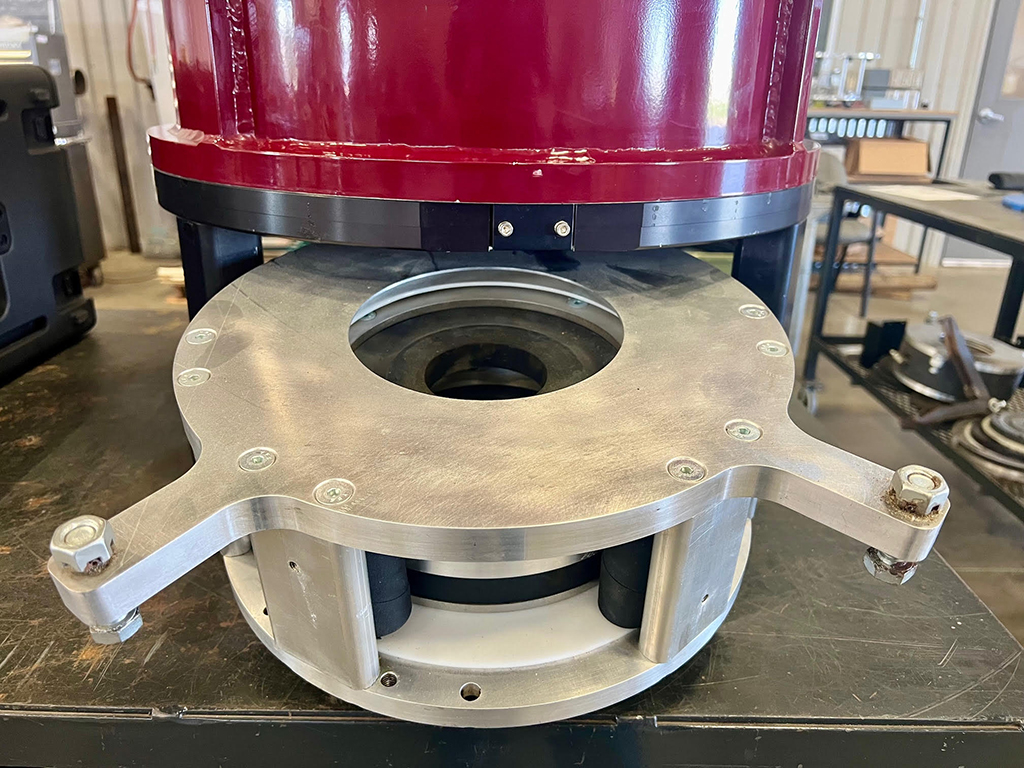

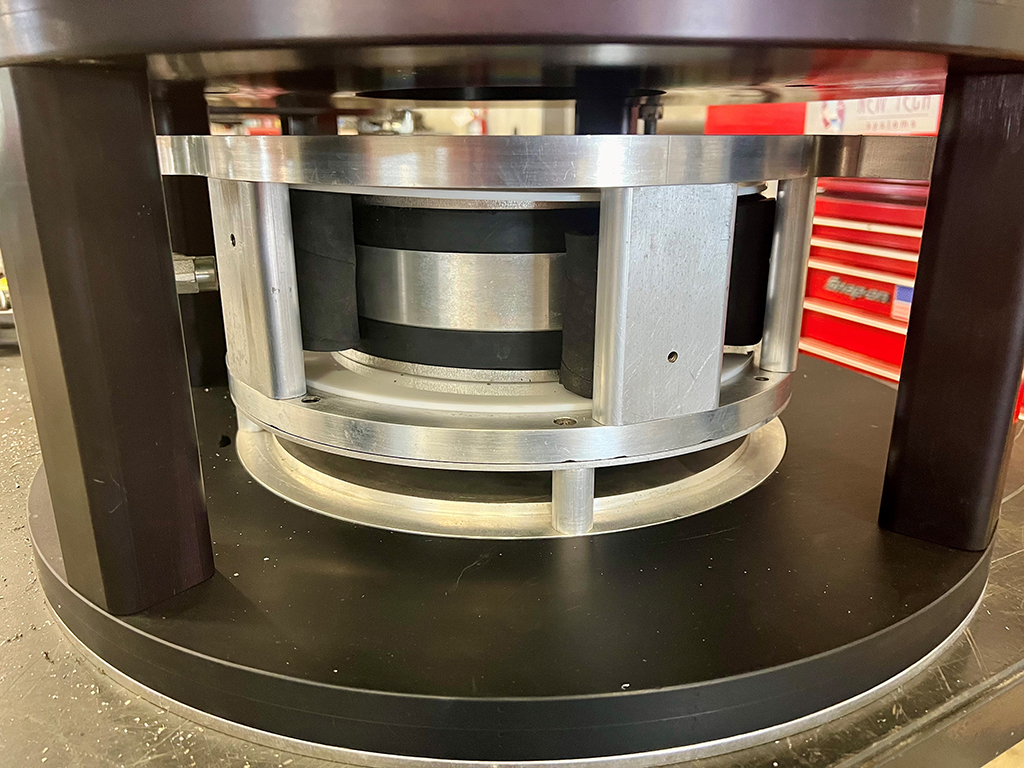

Product Images

Mode of Operation

The system is calibrated before being installed on the well servicing rig floor. The rig will normally pick up the inspection head/canister and lower it onto the pipe being held in the slips. After the head is in place, the cables are connected, and the pipe is pulled through the head, with 1 or 2 tubes being pulled at a time. The inspector observes the signals on the computer and determines the classification of the pipe condition based on the data presented in "real-time" on the computer screen. The rig crew breaks the tubing coupling apart, sets the 1 or 2 inspected tubes to the side and the process is repeated for the duration of the well. There are usually two people required to operate the WellTech 5™ system, being the rig helper and the inspector. The inspector will tell the rig helper to instruct the well service rig operator to either reject the pipe due to flaws or reuse it in the well. Classification color bands are normally painted on the pipe immediately after it is inspected, according to the inspection criteria. The WellTech 5™ operates with a high production rate, quality of inspection and excellent reliability.